The Art of Cheese Curd Creation

There are three components that are vital to the conception of each taste-bud titillating cheese curd: cheese, batter and a fryer. We will eventually get into the nitty gritty but I beg your forgiveness for indulging in this metaphor beforehand, I can’t help myself.

In elementary school one of the big projects in art class was to make bowls out of clay. In this analogy clay is the cheese because they are each the base material and both taste good (just kidding, you can’t prove I ate any and my friends are notorious liars). There can be slightly varying shapes and sizes, or you can pick an unusual cheese, but for the most part a bowl is a bowl. Once the bowl is crafted it goes into a kiln where it is heated to a high temperature and takes its final shape. The deep fryer, like the kiln, is what really brings the cheese curd to life. Adding colorful gloss in imaginative patterns allows the young artist to add a personal touch and let their creativity shine through. A good beer batter is the food preparer’s way to differentiate their work and experiment until they reach the texture and shade that fits their eye.

I realize the order of operations doesn’t match up but you get the point. Actually, now that I think about it this would have been a lot better analogy for chicken wings…but I already bought this domain name so we must push forward.

Cheese

Cheesemaking is the controlled spoiling of milk through a regimented process that results in a predictable, consistent product. First, bacteria that feed on lactose are added to the milk and those beautiful bastards ferment it into lactic acid. After that rennet, which is an enzyme, is added. To avoid getting too scientific let’s rename it Randy and pretend we hired him to help us with this next step. So, Randy shows up for work that first day and see a lot of potential but not much production. He doesn’t have the expertise to help directly but being a good manager he knows that he can facilitate and get the milk fat to do what are best at, curdling. Randy goes over and gives them a pep talk and the newly inspired milk fats pulls together and forms curds.

Randy’s work is done and once the curds are ready they are separated from the whey and dehydrated. Salt is also added to stop the bacteria from producing more lactic acid, plus salt tastes good and works to preserve. There are several more steps required to turn the cheese curds into the blocks of cheese you buy at the store but this is as far as we need to go.

Beer Batter

Beer batter has a consistency similar to pancake batter and is a brilliant way to add flavor and texture to a variety of deep fried foods. It is often used as a coating and acts as a barrier between the food being cooked and the hot oil of the fryer. This allows for flavor to be sealed in as the food is cooked very rapidly. Any two can vary significantly but most beer batters are a mixture of beer (usually a lager), water, flour, eggs and baking powder.

Deep Frying

Submerging food in hot oil, typically 350 – 400 degrees, is known as deep frying and it cooks the grub through conduction. The outside of the beer battered cheese curd is seared by the fry oil, which locks in moisture, and the inside is then cooked in a similar fashion to boiling an egg. As this is happening, steam exits and clashes with the oil creating many small bubbles around the curd. This process keeps the beer batter from becoming oily and instead results in the delightful, crisp exterior we enjoy encasing our melted cheese.

Cheeseheads

If you’ve ever seen a Green Bay Packer game on TV, or had the good fortune of visiting Lambeau Field, then you have undoubtedly seen many adult humans wearing faux cheese on their heads. The term cheesehead has long preceded the existence of the hat, starting as a derogatory term – to describe people from the Netherlands – meaning stupid or dense. The Dutch were skilled cheesemakers and know for crafting fine dairy products so eventually, as Wisconsin established itself as the leading dairy producer, the moniker became associated with residents of the Badger State.

After some time the expression would be used by opposing fans, Chicagoans for example, to heckle supporters of Wisconsin teams. Ralph Bruno embraced the good-natured derision, and in 1987 came up self-deprecating response. Using the foam from his mother’s couch cushion he crafted a cheese shaped hat. Shaped like one-sixth of a wheel of Gouda, the hat was then painted the color of cheddar and holes were burned into the foam to resemble Swiss. Once completed, Ralph wore it for the first time to a Milwaukee Brewer game in Chicago, versus the White Sox, and was struck by all of the attention his head wear garnered.

Later that year Ralph started a business and started selling his hats. Bruno says that he didn’t think too deeply about his design but the fact there was no actual cheese with matching characteristics to his hat he was able to secure several trademarks, giving him a lucrative business advantage. His company is called Foamations Inc and their products are made from a polyurethane foam. The Original Cheesehead, triangular in shape, is likely the one you are most familiar with, but the color and pattern of holes has been used for a variety of creations. You can buy cowboy hats, crowns, top hats, fedoras, visors, sombreros – even things like ties, bras, koozies and coasters – or almost anything else you can imagine.

The Milwaukee, WI based company has made sales in all 50 states as well as 30 different countries. They have expanded their business to manufacturing many custom products with their famous foam. Additionally, they offer a series of tours of the factory – one of which allows you to make your own cheese hat (!) – or you can even get married in their event center!! Ralph Bruno and his company are an inspiring story and proof that a sense of humor, hard work and a little luck can turn even the silliest ideas into wide-reaching successes.

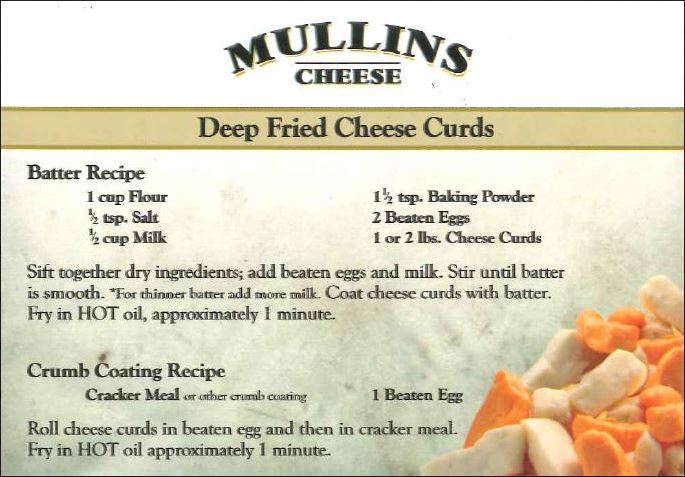

Homemade Deep Fried Cheese Curds, With a Recipe Courtesy of Mullins Cheese:

If you don’t have the good fortune of living in a place where deep fried cheese curds are easily accessible at restaurants, then I encourage you to try making your own! My wife and I recently decided to try our hands at this culinary adventure. The first step was to lay out our bag of cheese curds onto a cookie sheet and stick them in the freezer for about an hour. As those neared readiness we prepared the dry ingredients before stirring in the rest of the components for the batter.

We mostly stuck to the Mullins recipe but opted for a few tweaks – summoning unearned confidence that only truly naive amateurs could muster. We subbed in buttermilk, and a bit of beer, for milk and added a dash of pepper and garlic salt for a flavor twist. Once everything was set, we pulled the curds out of the freezer and dipped them into our concoction until they were thoroughly coated and ready to be fried.

Everything was going great until this point. We were using a pot to heat the peanut oil over the stove but couldn’t find our thermometer. So, we had to wing it as far as the temperature of the oil was concerned (it is supposed to be between 350 and 400 degrees). Our first batch burned almost immediately. The oil was too hot, so much so that it started smoking profusely and we had to hurry the whole pot outside. Once that simmered down we worked up the courage to try again. This time when we put the curds in they casually floated around like a sunburnt dad in a lazy river. The oil wasn’t hot enough and the curds turned into a greasy, congealed mess of lukewarm cheese.

The process was somewhat of a fiasco but eventually, like Goldilocks, we found the setting that was just right and the end result was really enjoyable. The curds bubbled and hissed before turning a beautiful golden brown about 60-70 seconds after getting dunked into the pot. We are eager to learn from our mistakes and try again soon, because the last batch of curds had great taste and consistency. There was something fun and satisfying about creating our own custom deep fried curds at home, and hopefully you will experiment too!